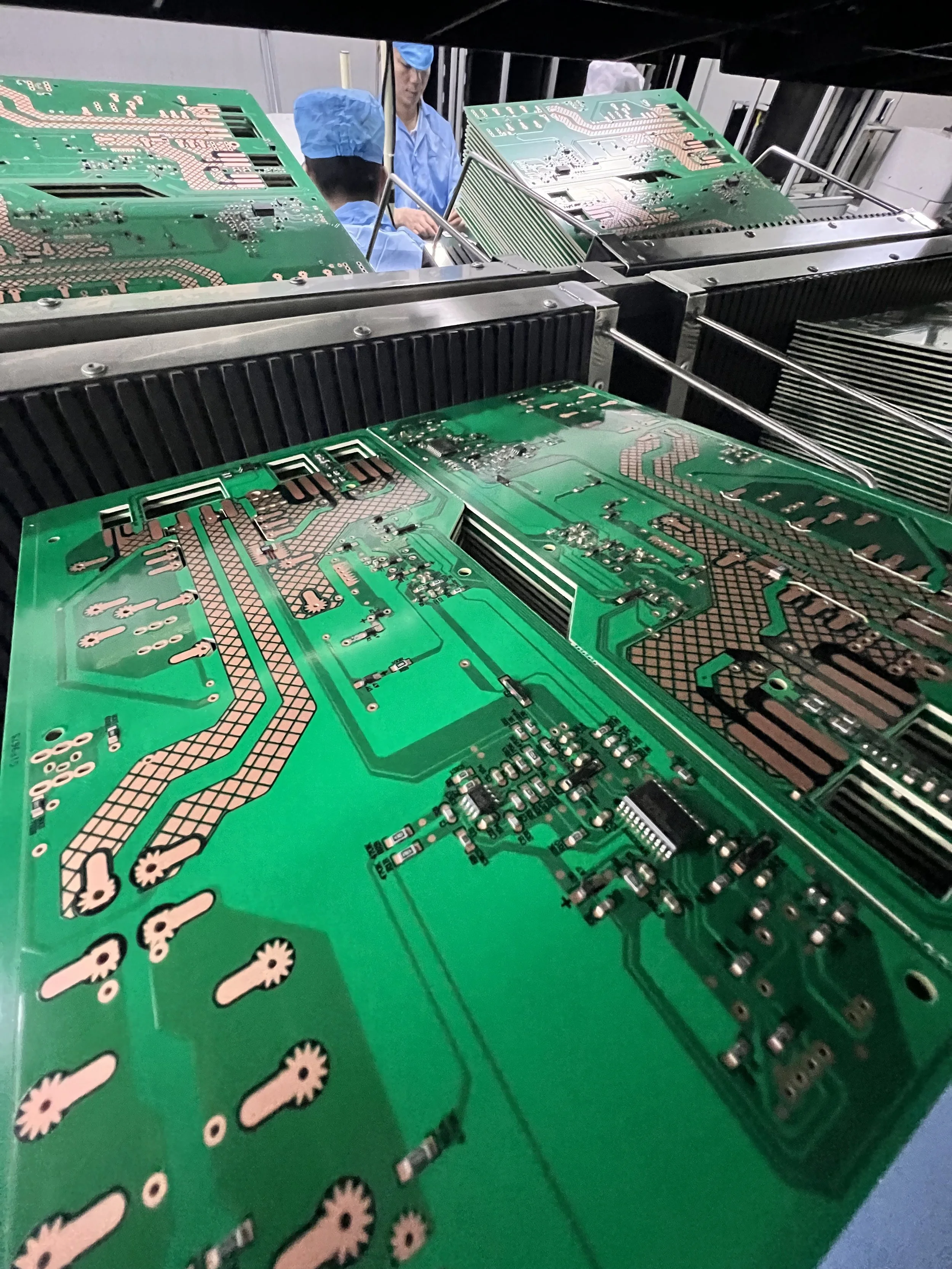

Not all factories in China are the same. We only work with top-tier manufacturing plants - the kind that already produce for leading global brands in kitchenware, household goods, and beverages.

Our on-the-ground team operates across South China (Guangdong / Pearl River Delta) and the Zhejiang belt (Hangzhou region), shipping mainly via Guangzhou/Nansha in the south and Ningbo–Zhoushan in the north.

Our role is not to “shop around suppliers”. We embed our process into a small group of factories, secure reserved capacity on their lines, align on quality standards and tooling practices, and then give you access to that ecosystem under a single, audit-ready process.

Partner Factories

Dedicated partner factories across three industrial clusters in China

Guangdong – Metal & Plastics for kitchen & home

Across our Guangdong and Zhejiang footprint, we work with a small network of partner factories.

With these factories, we develop most of the products our customers need, as they are based on the following clusters:

Electrical and digital appliances,

Cutlery, Knives & knife blocks, sharpeners,

Choppers, slicers and graters;

Pots and pans;

Kitchen utensils, accessories and gadgets

Thermoses and vacuum-insulated bottles.

Food storage containers

The tooling, materials and QA systems we use for kitchen & home also translate into adjacent categories, including:

Metalforming: cutting, pressing, deep-drawing, welding,

Injection moulding: TRITAN / PP / ABS / PC, overmoulding, assembly

Surface finishing: polishing, brushing, powder coating, PVD, laser marking

Double-wall stainless steel bodies (304/18-8, 430)

Vacuum creation and leak testing at scale

Powder coating and high-durability finishes

Bending/Forming

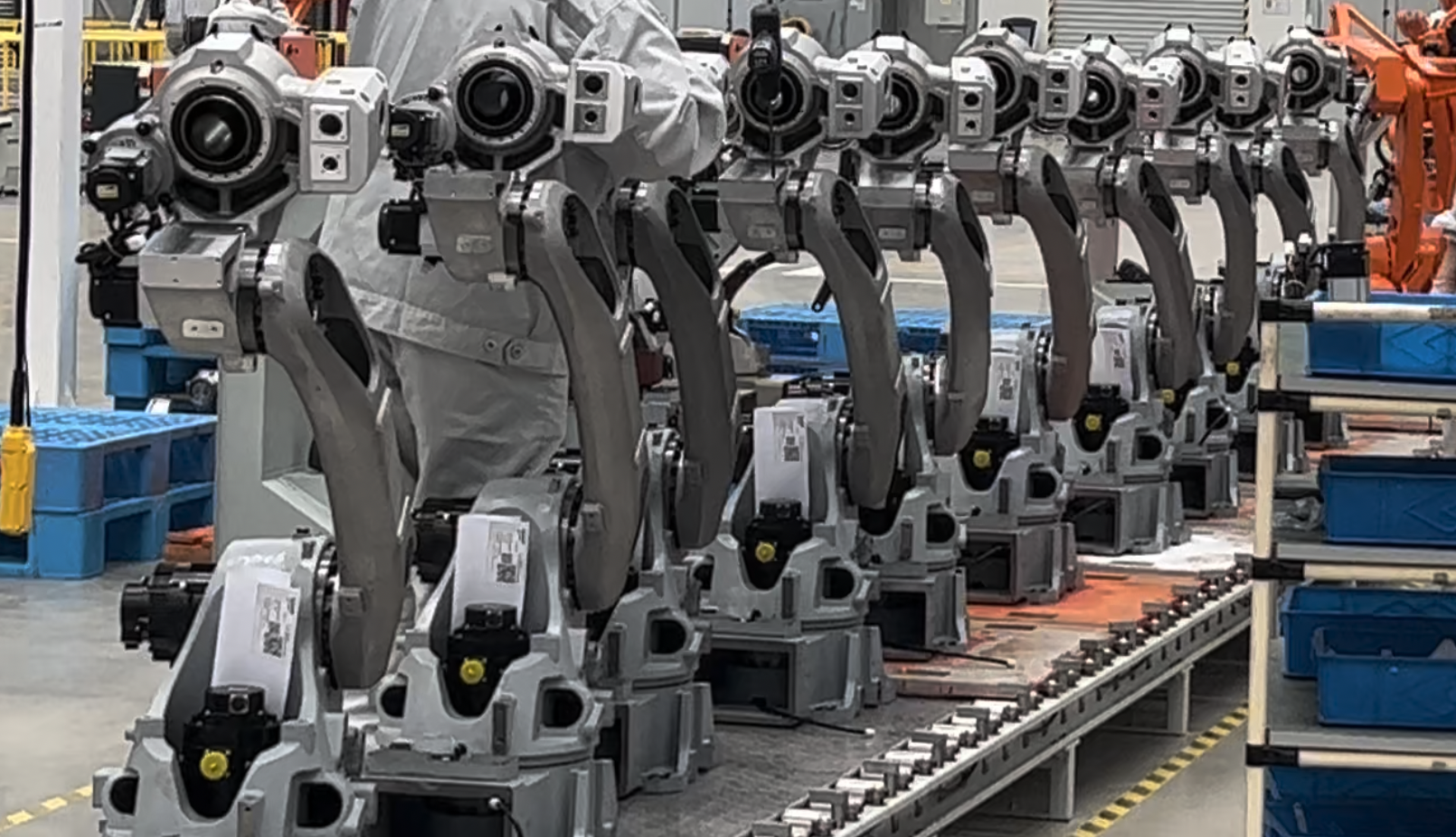

Robotic Polishing and brushing

Robotic Welding

Stamping

CNC Machining

Automated/Semi-automated Assembly Lines

Metal Processing

Welding and Joining

Wire Bending and Forming

Laser engraving and branding

Assembly & packing: retail packaging, sets, gift boxes, bulk packs

What “Top-tier’ Actually Means

When we say “top-tier”, we’re not talking about marketing slogans. We mean factories that:

Run documented quality systems (e.g. ISO-style procedures), not just “visual check”.

Have modern equipment and properly maintained moulds, tools and jigs.

Already manufacture for leading global brands in kitchen, home and drinkware.

Are used to third-party audits (BSCI / SMETA, retailer audits, etc.).

Can provide process capability and consistency—not just a nice showroom.

Understand and work regularly with LFGB / FDA / food-contact requirements.

We give you access to the same factories that manufacture for the leading global brands*

Our job is to find and secure those factories, maintain the relationship, and keep the bar high—so you don’t have to test your luck in a long list of suppliers.

*Disclaimer: Logos represent brands manufactured by our partner factories. BridgeWorks is independent; no endorsement is implied.

Quality Assurance

Quality is a process, not a promise

We don’t leave quality to the last inspection. We define it upfront and apply it throughout the build.

Golden sample as reference

No production without a signed-off golden sample (finish, feel, fit, branding).

Three-point QC plan

IPP (Initial Production Check): set-up, first pieces, process control • DUPRO (During Production): catch issues before they propagate • PSI (Pre-Shipment): final check against golden sample and spec.

AQL-based inspection

Typical plan - Critical: AQL 0.0 • Major: AQL 2.5 • Minor: AQL 4.0. General Inspection Level II, adjusted if your category requires tighter control.

Corrective action

If defects exceed agreed limits, we don’t “hope for the best”. We define rework, reinspection and, if necessary, sorting or remake - before cargo is released.

Testing & Compliance

Testing and compliance for kitchen, home and drinkware

Food-contact & safety

LFGB / FDA migration where applicable - Material certificates, test reports and traceability

Thermal & functional tests

Thermal retention vs. spec - Leak tests, drop tests, lid/closure performance

Finish durability

Adhesion tests for coatings - Corrosion / salt-spray when relevant

Packaging & transport

Basic ISTA-style checks to reduce transit damage - Labelling and regulatory marks for EU/UK/US and LatAm as needed

Tooling, Mould & IP

Tooling, moulds and your IP inside the plant

Your product doesn’t end at the CAD file; it lives in the moulds and fixtures on the factory floor. We manage that deliberately:

Tooling in your name

Moulds and tools are plated and recorded as your property, even if stored in the factory.

Custody and access

Tools remain at the plant under agreed storage and maintenance conditions; we can audit their state.

No third-party use

Your tooling is not to be used for other customers. This is reflected in factory-side agreements and our English-law contracts with you.

Intellectual Property alignment

Our global IP approach (transfer of design rights to you for EUIPO / UK IPO / USPTO or any other intellectual property registry) is mirrored in how we manage tooling and designs in China.

What This Means For you

Choosing BridgeWorks means your products are built in factories that already meet the standards of global brands, under a clear, auditable quality system - without you needing a sourcing office in China or a local engineering team.

You speak to us in your own language; we embed the right standards in the factory. The outcome is simple: fewer surprises, fewer quality problems, and products that are ready for real markets, not just nice samples.